Cable Winch W-30

A power-house for the forestry and construction industries

Brake systems

Holding brake:

- Shoe brake mounted directly in the drum

Driving brake optional:

- Air brake

- Dead man's brake (hydro spring-loaded)

- Eddy current brake

Power transmission

- Hydrostatic drive, continuously adjustable

- Mechanical 6-forwards-/reverse speed gearbox

- ditto with fluid turbo coupling

Motors

- 4 cylinder Deutz turbo diesel 55 kW/75 HP

- Electric motor

Set up and function

Thanks to its lightweight construction from high-quality aluminium casting, the Wyssen cable winch can be used in many applications in the wood and forest industries as well as in the construction industry. It is primarily used as a drive unit for cable crane systems and as a hauling device for heavy skylines, as a drive unit for inclined lifts and as a circular drive wheel for a material cableway. When fitted with a grooved pulley or a capstan ring, it performs valuable work as a circular drive wheel for a material cableway. The sled runners, which are supplied depending on the winch type either in narrow or wide versions, give it good all-terrain mobility, and for this reason it is also very suitable as a mounting winch. The continuously adjustable roller fairlead at the front serves a steering mechanism in terrain and the mountain stabilisers at the rear prevent the cable winch sliding backwards. The large drum diameters ensure a very long service life of the mainline. With just one control lever the speed, tractive force and direction of rotation of the cable drum can be adjusted to the particular conditions. Loads can thus be drawn, lifted, transported up the mountainside and lowered. Transport downhill is usually carried out with the air brake. This high performance brake, without any wear, permits a rapid descent with heavy loads. Wyssen cable winches are modular in construction, so that they can be adapted to the individual requirements of each customer. All spare parts are available from stock.

Options

The cable winch W-30 is available with the following options and accessories:

- wide sled runners

- electronic distance indicator

- Splash protector

- Protective cover

- Luggage rack

- Suspension gear

- Unimat drive (circulation with feed roller and swiveling deflection rollers)

- Circular drive wheel with Becorit lining or parabolic pulley

- Free-wheel for air brake

- Cable guide roller

- Overfill safety device

- Slack cable safety device

- Remote control

- Radio with automatic target

- Radio control with automatic guidance system

- Transport trailer

- Oil-cooled gearbox and filtration

Technical data

| Tractive Forces and Speeds W-30 | Drum Empty | Drum Half-Full | Drum Full |

|---|---|---|---|

| Gearbox model A | 9.42 m/s 2’980 kg | 11.30 m/s 2’555 kg | 13.19 m/s 2’129 kg |

| Gearbox model B | 8.29 m/s 3’500 kg | 9.95 m/s 3’000 kg | 11.61 m/s 2’500 kg |

| Gearbox model C | 7.86 m/s 3’690 kg | 9.43 m/s 3’163 kg | 11.01 m/s 2’636 kg |

| Gearbox model D | 6.92 m/s 4’192 kg | 8.30 m/s 3’593 kg | 9.69 m/s 2’994 kg |

| Gearbox model E (standard model) | 6.09 m/s 4’192 kg | 8.30 m/s 3'593 kg | 9.69 m/s 2’994 kg |

| Gearbox model F | 5.78 m/s 5’023 kg | 6.93 m/s 4’305 kg | 8.09 m/s 3’588 kg |

| Gearbox model G | 5.08 m/s 5’522 kg | 6.10 m/s 4’733 kg | 7.12 m/s 3’944 kg |

| Main Dimensions W-30 Cable Winch | Measures |

|---|---|

| Length | 2’900 mm |

| Width | 1’175 mm |

| Height | 1’220 mm |

| Drum-ø | 476 mm |

| Drum width | 832 mm |

| Total weight with winch | 1’572 kg |

| Cable Drum Capacity | Measures |

| Cable-ø 9.0 mm | 1’960 m |

| Cable-ø 9.5 mm | 1’880 m |

| Cable-ø 10.0 mm | 1’630 m |

| Cable-ø 10.5 mm | 1’390 m |

| Cable-ø 11.0 mm | 1’340 m |

| Cable-ø 12.0 mm | 1’110 m |

| Seil-ø 13.0 mm | 890 m |

| Cable-ø 14.0 mm | 840 m |

| Cable-ø 15.0 mm | 675 m |

| Cable-ø 16.0 mm | 604 m |

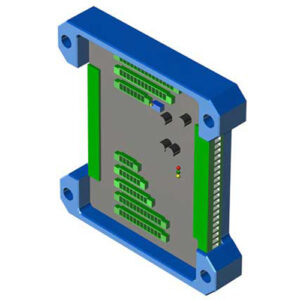

Wyssen Control System FSI 2007

The self-developed FSI control system is installed in the W-30 cable winch. The control is also mounted in the following machines: Carriage Slackpuller, Carriage Universal, Motorised Skyline crane, Cable winch W-40 and in the Cable Winch W-90.

Advantages

- operable with radio

- can be adapted for the existing radio remote control on the mobile cable crane

- automatically switches off when not in use

- clamping with a radio signal during the journey via set speed no longer possible

- Automatic emergency stop if the programmed speed limit is exceeded

- Display for setting the parameters

- All parameters can be individually adjusted (speed, clamping and delay times)

- Battery status display

- CAN-Bus interface

- Integrated 3D inclination sensor

- Resistant against moisture, vibration and impact due to completely enclosed electronics

- Plug is secured with screws

- Software updates with improvements and upgrading is possible at any time